Overview

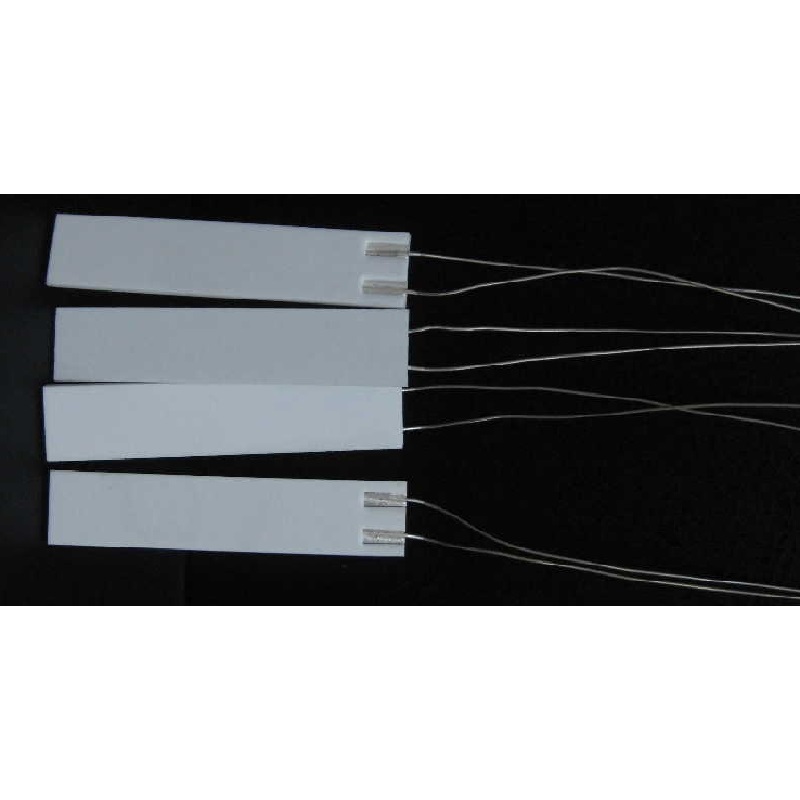

The insulating material is alumina ceramic usually, but others are possible, such as ceramic, glass, mica and so on. It can be used in hair straightener,hair crimper, film covering machine, and other appliances.

Details

2. Notice in appliance.

It’s rapid temperature rising, with small bulk, with high power in unit area. There is not temperature self-control character, temperature control circuit is needed. Over-temperature protector is needed for preventing failure of temperature control.

It’s rapid temperature rising, with small bulk, with high power in unit area. There is not temperature self-control character, temperature control circuit is needed. Over-temperature protector is needed for preventing failure of temperature control.

Single side insulator type consists of noble metal as heating material. It’s long life, no oxygenation. And various temperature coefficient of resistance can be selected.

Both sides insulator type consists of Mo-Mn alloy as heating material. It is longer life than wire heaters. It’s with temperature coefficient of + 2000~3000×10-6/℃. The power is changed slightly with temperature changing. Temperature control circuit is needed for controlling the temperature.

3. Current products.

|

part number

|

length

/mm |

width

/mm |

thickness

/mm |

resistance

at 25℃ /Ω |

insulator

|

high

pot/V |

rate voltage/V

|

max. temperature

/ ℃ |

|

TCS-100R110L24W120V

|

110

|

24

|

1.0

|

100±10%

|

single side

|

1500

|

120V

|

250

|

|

TCS-100R110L15W120V

|

110

|

15

|

1.0

|

100±10%

|

single side

|

1500

|

120V

|

250

|

|

TC-50R70L20W120V

|

70

|

20

|

1.3

|

50±10%

|

both sides

|

3000

|

120V

|

250

|

|

TC-70R70L15W120V

|

70

|

15

|

1.25

|

70±10%

|

both sides

|

3000

|

220V

|

250

|

|

TC-70R70L10W120V

|

70

|

10

|

1.25

|

70±10%

|

both sides

|

3000

|

220V

|

250

|

|

TC-70R70L07W120V

|

70

|

7

|

1.25

|

70±10%

|

both sides

|

3000

|

220V

|

250

|

|

TC-160R70L20W220V

|

70

|

20

|

1.3

|

160±10%

|

both sides

|

3000

|

220V

|

250

|

|

TC-160R70L15W220V

|

70

|

15

|

1.25

|

160±10%

|

both sides

|

3000

|

220V

|

250

|

|

TC-160R70L10W220V

|

70

|

10

|

1.25

|

160±10%

|

both sides

|

3000

|

220V

|

250

|

|

TC-160R70L07W220V

|

70

|

7

|

1.25

|

160±10%

|

both sides

|

3000

|

220V

|

250

|